Workshop Information

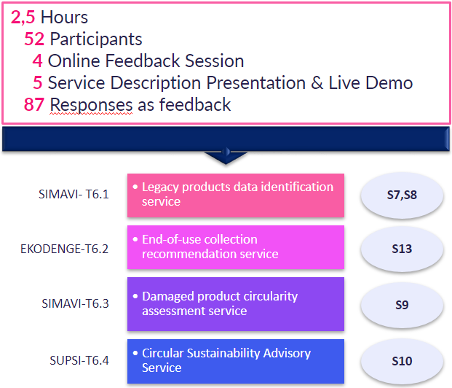

On 15 March 2023, EKODENGE realized a demo of the first version prototypes for the first four Tasks of WP6 with three Task leaders. This demo was a fourth milestone from twelve milestones of the project. The format of workhop was online. The presentation lasted approximately two hours and a half with fifty two participants consisting of consortium members. Also, it was a two-sided presentation with online feedback session, taking ten minutes for each Service demo.

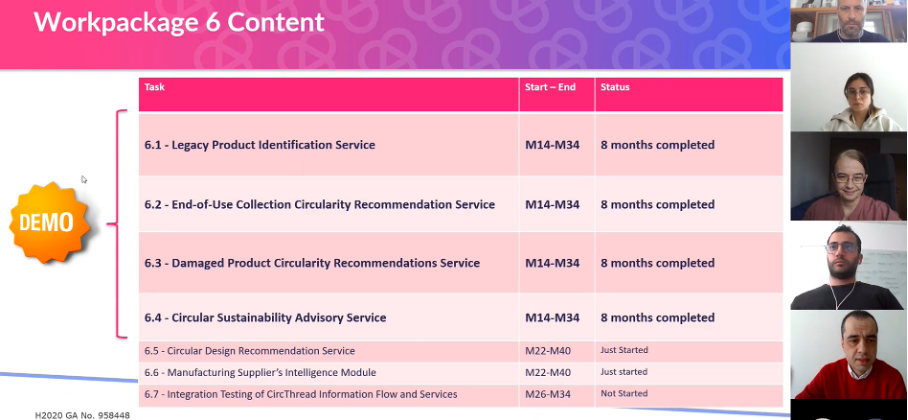

WP6, named as flexible decentralised circularity and sustainability Services, with its six Tasks delivers Circular Economy Software Service modules to interface with the Digital Thread information exchange system via the Services container. To this end all Tasks will identify using the use cases, the required data and Service delivered information linkages across the life cycle, the backend algorithms and the user interfaces on a decentralized basis. The main objective of this WP is to support the assesment and decision making in the product life cycle.

Aim and Targets of the Workshop

The main target of the workshop is to share current state of the Services with WP6 Task leaders and all consortium members during workhop. Even if these are not complete and fully functional software systems, the importance of feedback is emphasized both as a milestone in the proposal of CircThread project and in our approach. It also supported our agile approach that we have been using to conduct software development methodology. With agile approach, we’re going to work with iterative approach and two week sprints. Therefore, we organize a webinar so that all consortium partners are aware of the current state of the Services and can give feedback.

Presenter Partners and Their Services

SIMAVI is a Task leader of Task 6.1, which is legacy products data identification Service and Task 6.3, which is damaged product circularity assessment Service. They have presented Service 7, Service 8 for Task 6.1 and Service 9 for Task 6.3.

NIRwave Pico is a compact embedded NIR spectrometer with integrated AI-supported engine in order to perform sampled material classification. The system has been so far successfully utilized in textile classification. In the scope of CircThread, for Service 7, the apparatus will be extended to support polymer material classification for appliances during their pre-treatment and recycling, in the scope of the end-of use decision use case.

Service 8 will be developed for use by a collector or Producer Responsibility Organisation (PRO) and by recyclers. The Service will enable the user to provide product information for legacy end-of-use products in a webService to fill gaps where no information is directly available from the original manufacturer. The main purpose is to approximate as closely as possible the individual products materials and components composition to generate a bill of materials.

Service 9 will be developed to capture information about collected products. Specifically, to capture the level of damage of a product in transit or in-use in order to obtain a real evaluation of the best end-of-life processing.

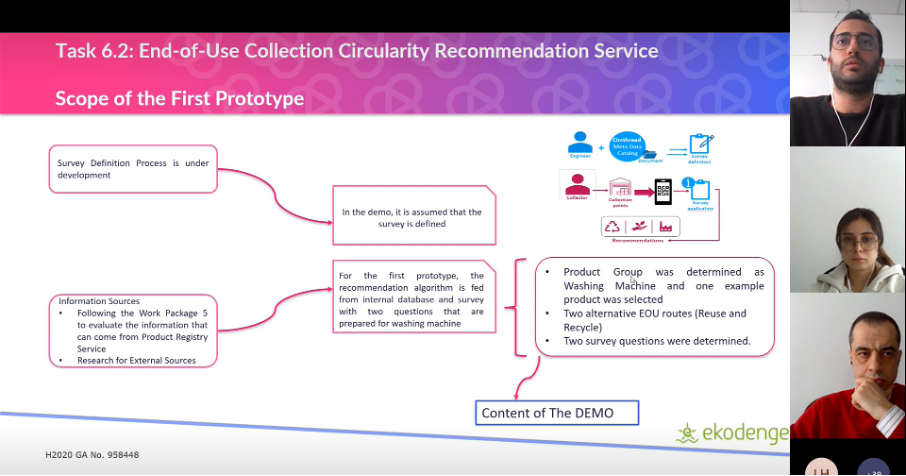

EKODENGE is a leader of Task 6.2, which is end-of-use collection recommendation service (Service 13). The Service will be developed based on three modules. A product information module will provide an overview picture of the state of the appliance when collected. A circularity assessment module will be based on the state of the appliance to evaluate the material and product circularity benefits of different end-of-use options. And a market-value database for different end-of-use routes will be developed to provide for economic information based on the end-of-use options and recommendations. The combined circularity and economic information can then be used for a collector or Producer Responsibility Organisation (PRO) to decide the end-of-use or end-of-life route upon collection.

SUPSI is a Task leader of circular sustainability advisory Service (Service 10). The Service aims to support products analysis from a combined sustainability and circularity perspective. It will do so by computing a set of assessment indicators given available product manufacturing, use and supply chain information, to support manufacturer’s decisions to improve the product circularity, environmental and social performance.

Workshop Analysis and Action Plan

After workshop analysis, the feedback was gathered and transferred to Task leaders to be able to enhance their Services considering valuable contributions. We have got 87 responses and Ekodenge has compiled all feedbacks that came from surveys at the end of each Task presentation. Each feedback has been sent to partners, individually. In the further steps, this feedbacks will be taken into account on developing phases. In addition, the early stage feedback technique suggested by agile methods was beneficial. Stakeholders from different perspectives had different feedback, and useful information was generated at an early stage for Service development teams to make their applications more efficient and useful.